Challenger Remote PC’s

Please note that our GECMA Challenger and Explorer ranges have now reached the End of Life and are in the termination process. The accessory components will continue to be supported for spares and repairs only until approximately December 2020 or until further notice. More detail can be found within the table below.

Why not take advantage of our new generation of HMI by upgrading to the MTL GECMA Work Station range. Have a look at our MTL GECMA Work Station upgrade brochure here.

This innovative operating terminal boasts a unique modular design concept, state-of-the-art technology and is packed full of valuable features. With various upgrade options available and mechanical backward compatibility*, you do not have to undergo a complete re-install.

*special conditions may apply

| Product Termination Notice and ‘Last time buy’ | |||

| Statement issued | Product | Last time buy | Replacements and/or notes |

| 05 December 2016 | As listed below | 31st March 2017 | MTL GECMA Work Station |

| 05 December 2016 | As listed below | 30th June 2017 | Last shipment for full terminals |

| 05 December 2016 | Accessories | Estimated Dec 2020 |

Supported for spares & repairs only |

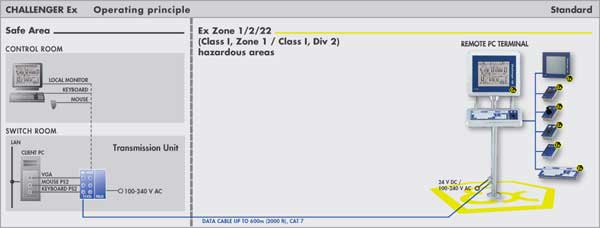

The CHALLENGER range of remote PC terminals are designed for use in extreme hazardous areas such as those encountered in Pharmaceutical, Chemical, Biotech and Oil and Gas industries. CHALLENGER Terminals can be configured in a modular manner to meet with the plant installation requirements. All the components including the display, touch screen, keyboard, pointing devices, etc. - are certified for use in hazardous areas as control panel-mounted modules and can be mounted independently into various enclosures / walls or into our CHALLENGER FHP standard enclosure which provides environmental protection.

CHALLENGER components are modular thus allowing for individual configuration in the most diverse of production plants. All electronic components such as displays, keyboards, pointing devices, etc. are designed as panel-mount modules and can be mounted in our enclosures as well as in existing cabinets. The metal and plastic materials used are based on long-term experience in hazardous and industrial areas, and resist the strongest of impacts. Specially tested materials for sealings ensure the IP66 / NEMA 4X protection, which is often required.

To download a copy of the overview brochure <click here>

To download a copy of the Challenger 22i upgrade brochure <click here>

Symbol denotes that the equipment is suitable for use in hazardous area applications.

Symbol denotes that the equipment is suitable for use in hazardous area applications. Symbol denotes that the product has been assessed for functional safety applications

Symbol denotes that the product has been assessed for functional safety applications